Competences

In the field of special machine construction, many skills and competences are similar across the industry. Our core competences in the realisation of automation tasks are:

Analysis and advice for your automation project

The analysis with subsequent consultation is the start of a successful cooperation. Involving PROAUT TECHNOLOGY GmbH in your automation project as early as possible is crucial for success. As early as possible can mean during your product development. Because it is possible that small changes in the design of your product will significantly simplify automation and thus reduce future production costs.

Please simply contact our sales manager

Holger Salzer

Phone +49 30 530 24 89 12

Email: h.salzer@proaut.eu

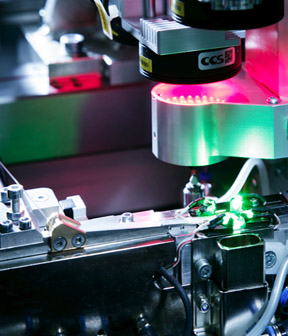

Electrical and optical measurement

For checking individual measured values in series production and for quality assurance of highly complex components, we integrate customised measuring and inspection systems into our special machines. High-performance image processing systems enable 100% inspection of parameters that are important for you.

- Integration of measurement technology for all electrical variables

- Camera and laser-based measuring systems for mechanical variables

- Measurement accuracy in the μm range, in 2D and 3D

- Measurement under extreme conditions such as vacuum, overpressure, noise protection

- Development of matching circuits and integrated illuminations

Handling

With the constantly advancing miniaturisation, the demands on speed, precision and reliability of the handling systems are increasing at the same time. New surfaces, materials and properties of the components require new handling solutions.

More than a decade of experience in special machine construction, especially in the development and construction of handling systems, flows into our special machines. PROAUT TECHNOLOGY GmbH has technical experience, such as:

- Handling of small components, for example 0.3 x 0.6 mm², gripping and depositing without tension

- Highest positioning accuracy in the μ-range in 4 axes

- Flat support and fixing of foils with a thickness in the μm range

- Processing of coated films on rolls with a thickness in the μm range

- Highest reliability through camera monitoring

- Support through integrated measuring systems

Assemble and pack

We have extensive know-how in the packaging of components in stick, tray and belt systems. The belt pockets of the tape and the rotational position of the components can be monitored by means of image processing. Assembled components can be easily transported, stored as well as automatically processed without any problems.

The assembly of components can include all types of joining techniques, for example gluing, screwing, welding. Integrated quality monitoring and statistical process control monitor all operations. PROAUT TECHNOLOGY GmbH can offer the most diverse types of component packaging with our developed special machines.

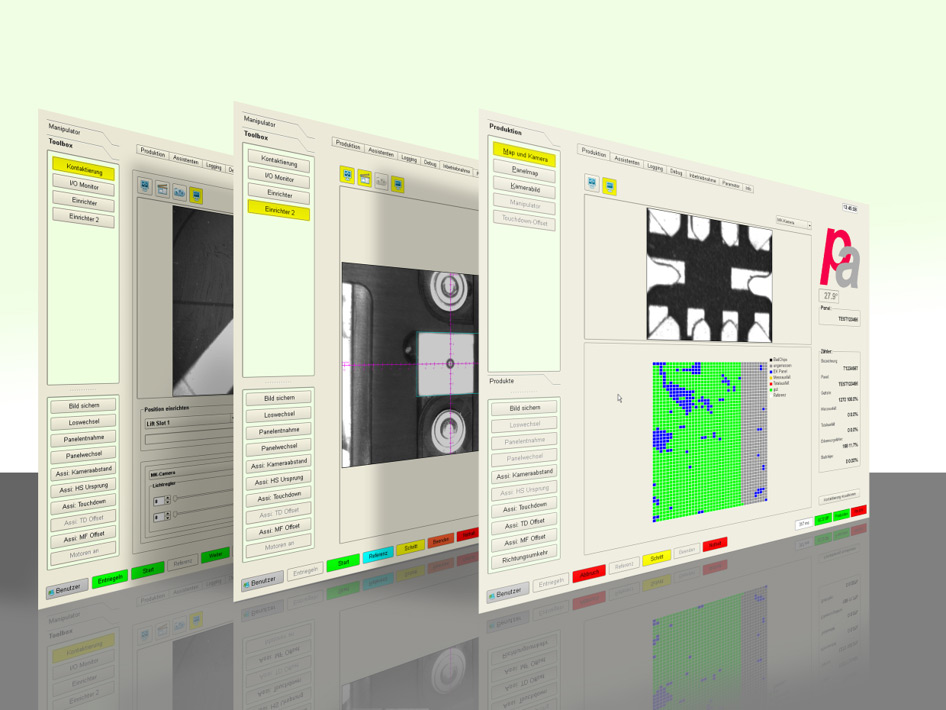

Software and image processing

Based on modular control software, we develop machine-specific applications in close cooperation with our customers.

Robust software with many safety functions

Intuitive operation, support through dialogues, help texts and assistants

Integrated image processing for process control

Traceability of the product over all process phases possible

Laser marking and cutting

Laser marking systems are the preferred method for marking components in our special machines and test stations. There are many reasons in favour of laser marking:

- Precise micro-marking on small components

- Character heights from 100 μm

- High reliability

- Short marking times

- Processing of different materials

- High durability of the marking

- Variety of marking types (plain text, DMC, images, CAD, logos, barcode, etc.)

- Alternatively, printing techniques can also be used. PROAUT